There’s plenty of talk these days about disruptions to the global supply chain, but it’s not a new discussion.

By the middle of 2019, 72% of the facilities making active pharmaceutical ingredients (APIs) to supply the US market were located overseas, leading many businesses based in the United States to rebalance their relationships with foreign nations and supply chain diversification for APIs.

Global Risk, Domestic Emphasis

As lockdowns rippled around the world when the pandemic worsened, factories and research facilities shut their doors and stalled the work of their global customers.

Today, continued concerns about global or regional COVID-19 lockdowns, potential tariff wars, labor shortages affecting import/export, and geopolitical instability like warfare in Ukraine are the latest factors prompting companies to replace overseas suppliers subject to heightened uncertainty with more reliable domestic vendors.

Many companies that operate with overseas facilities are understanding as part of their risk/benefit analysis that the risks of maintaining offshore research and manufacturing now outweigh any fiscal benefits they might enjoy.

Bringing Business Home

Security concerns aside, there are valid arguments to be made for, as an example, the importance of generic drugs that will be sold to Americans being made domestically to avoid inevitable supply chain and transportation disruptions.

Additionally, more domestic science-based manufacturing means the opportunity for improved material purity, process efficiency, R&D cost control and IP protection, as well as for innovations to take place within our own borders and better alignment with US regulatory agencies like the Food and Drug Administration.

Reshoring Done Right

It’s no coincidence that with the number of overseas contract research organizations (CROs) facing a new round of volatility, Adesis is seeing a growing interest in our 100% US-based company. In fact, new inquiries from potential customers generated from Adesis client and employee referrals saw an increase of more than 40% during Q1 of 2022.

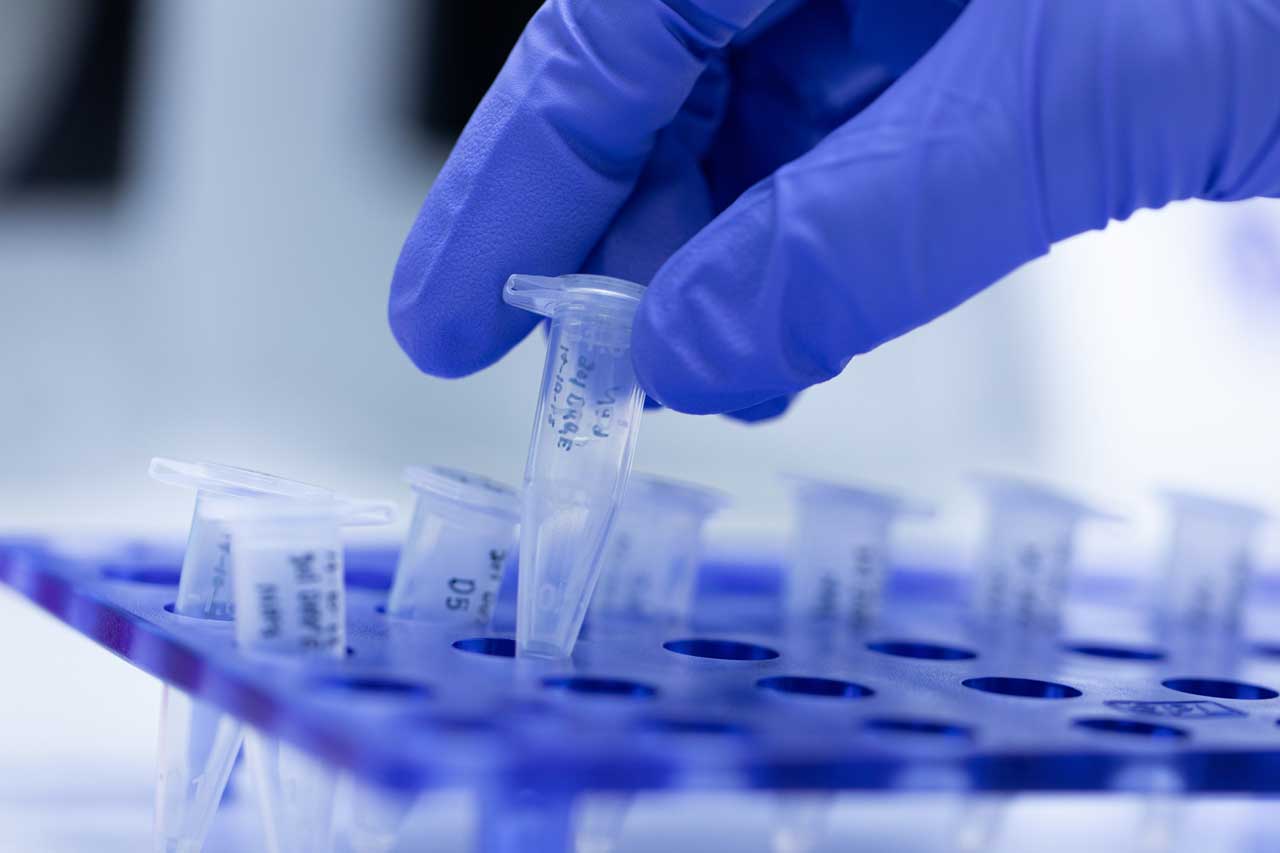

Part of that could be due to our dedicated team of Ph.D. chemists, many of whom came to us from the pharmaceutical industry, and who take ownership of each project. Not only are they accountable and personally invested in being the best for our clients and colleagues, they’re not shy about sharing their great experiences working at Adesis.

Perhaps it’s our prime location in the center of the Mid-Atlantic pharmaceutical hub, allowing for real-time communication with fewer worries about time zone delays.

Focus on Innovation

It could also be our new 30,000-square-foot space that includes 17 chemistry laboratories, including large labs for analysis, sublimation and purification. Our top-to-bottom system allows for the fundamental research all the way through scaling a product up for manufacture. We also maintain highly specialized equipment thanks to our organometallic chemistry work with parent company UDC.

Of course, it might be our commitment to our clients’ success. We form strategic partnerships with our clients to better understand their chemistry problems and accelerate workflow, addressing chemistry challenges in ways that minimize costs, increase scalability and allow products to go to market faster.

If your company is looking for a US-based CRO that provides reliability, stability and a vested interest in your project’s success, let’s talk. We’d love to give you an idea of what you’re missing.