An innovative, agile extension of your R&D team.

With extensive experience in chemical process development, we are innovators, committed to delivering cost-effective, safe and scalable chemical processes.

Discovery Chemistry answers the question: What to make?

Process Chemistry answers the question: How to make?

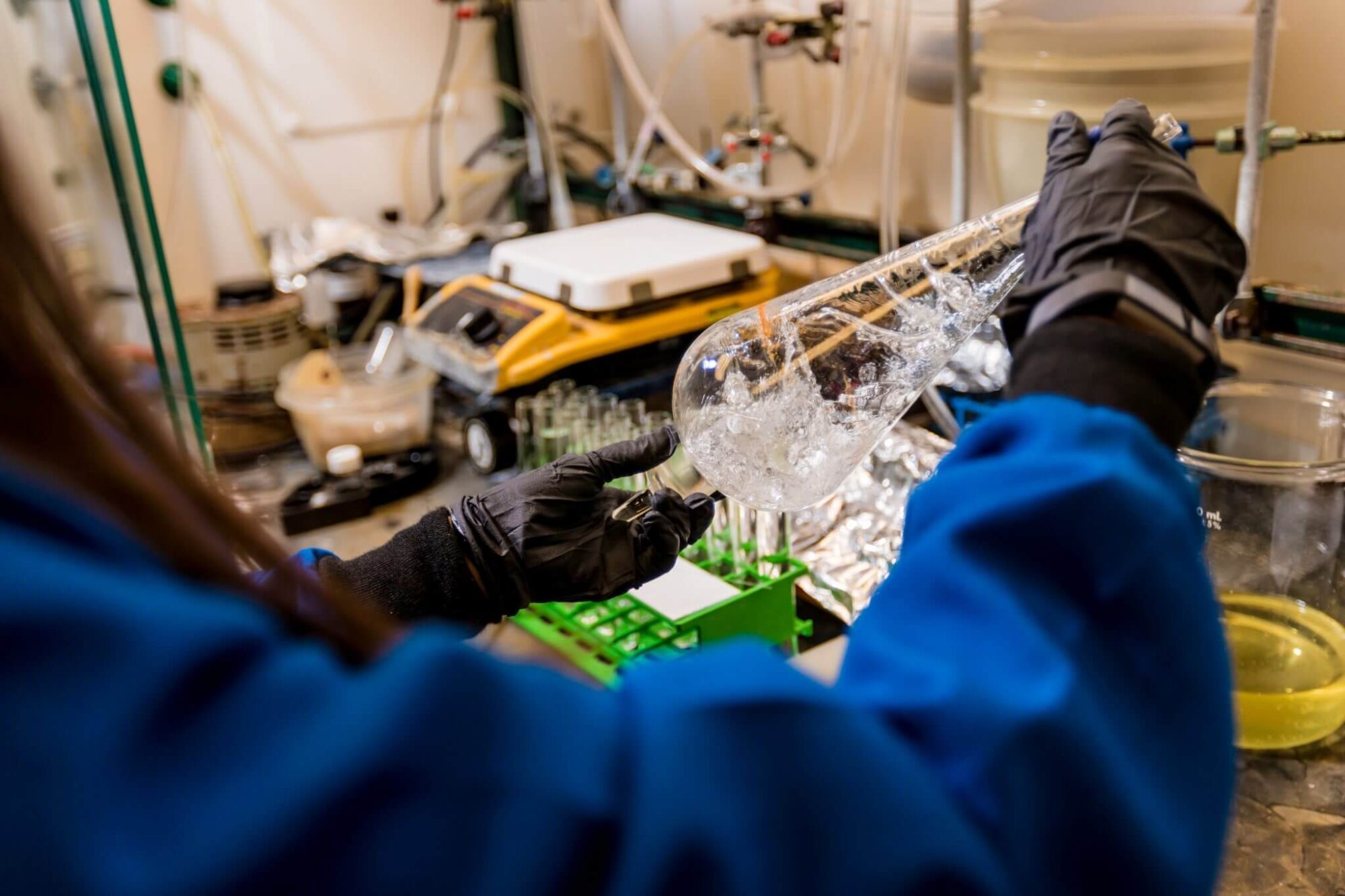

Adesis’ process development team optimizes small-scale chemical synthesis and prepare it for the multi-kilogram manufacturing level. Our expert scientists will engage with you to follow or enhance your scale-up process, or design and execute a cost-effective scale-up process – quickly, safely and to the highest purity and quality.

- Route scouting and selection

- Fit-for-purpose process development to enable expedited synthesis in the 1-5 kg range

- Process development and non-GMP synthesis to deliver intermediates, specialty chemicals and APIs on multi-Kilo scale

- Organic and organometallic synthesis

- Heterocycles

- Deuteration

- High purity monomers

- Process intensification

- Process development to enable cGMP manufacturing

- Process hazard evaluation (DSC, TSu and reaction calorimetry)

- Synthesis and isolation of impurities

- Fate and purge of impurities

- Process consistency studies

- Design of Experiments (DoE)

- Study critical process parameters and operating ranges

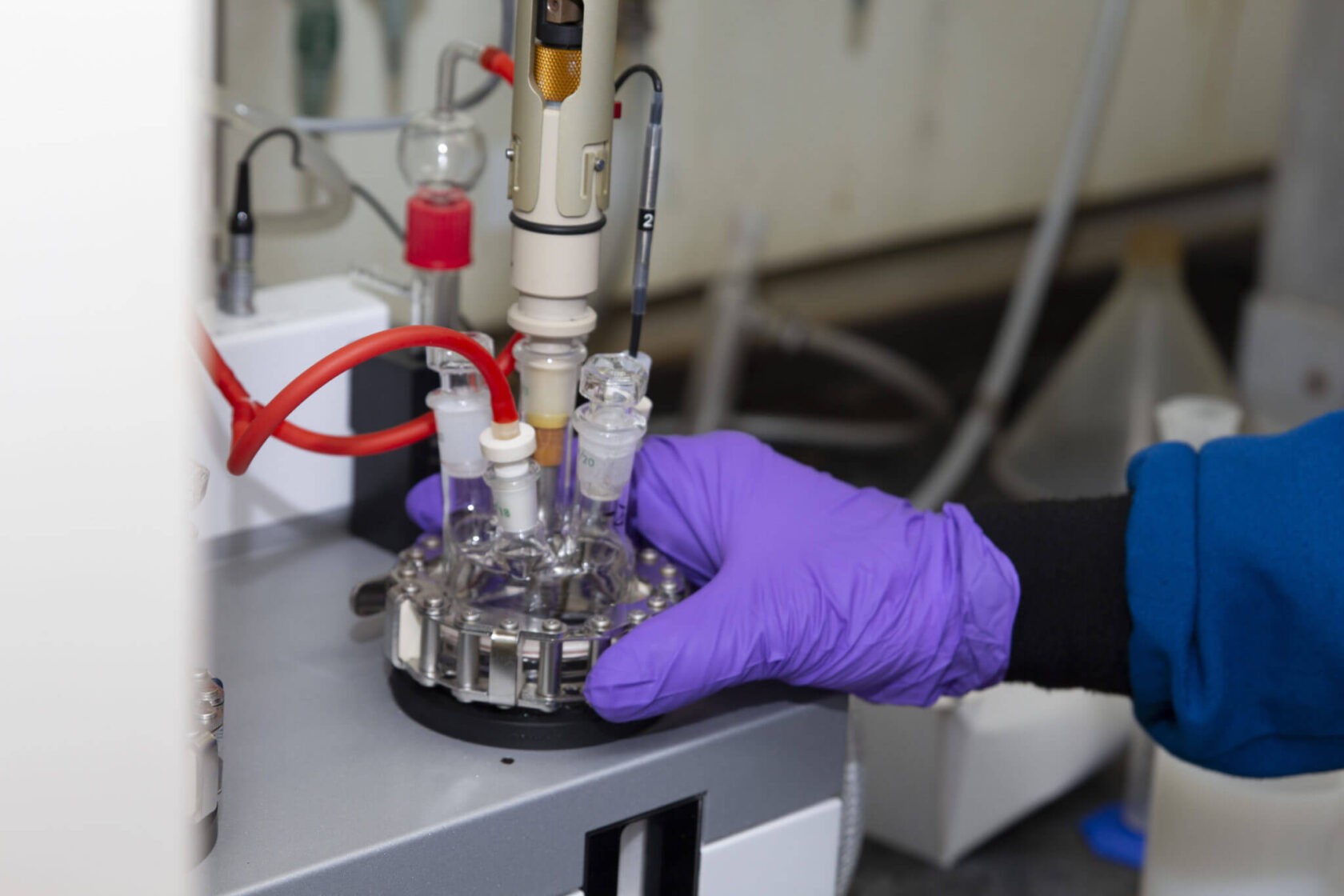

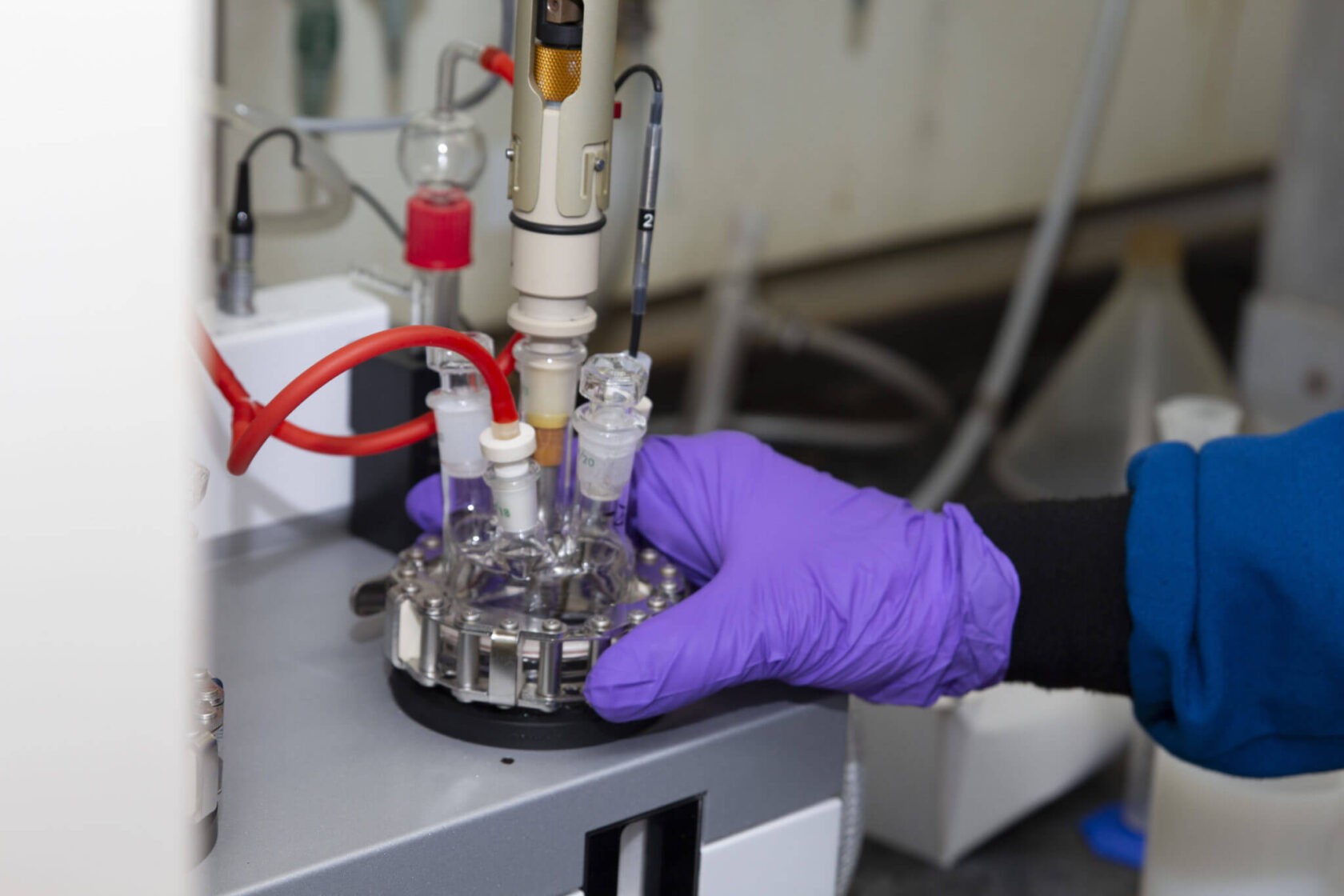

Our continuous flow chemistry capabilities can optimize your chemical processes, leading to significant reaction improvements and cost reductions in labor, raw materials and waste.

- Three fully automated systems for reaction optimizations, and an automated reagent injectors that can be programmed for up to 120 reagent combinations in one run

- Accurate flow rate from 1 µL/min to 10 mL/min per channel, expandable to 50 mL/min per channel for production use

- Pressure up to 5000 psi

- Large collection of reactors (1 mL to 60 mL) and ability to design and fabricate reactor to meet customer need. Materials: PTFE, HPFA, hastelloy, stainless steel, borosilicate, and quartz

- Dedicated photochemistry equipment

- Gas addition module for reaction involving hazardous or high-pressure gas, i.e., H₂, O₂, CO, etc…

- Solid phase reactor

- Temperature range: -30 °C to 300 °C

- Experienced in mg to 100s g synthesis

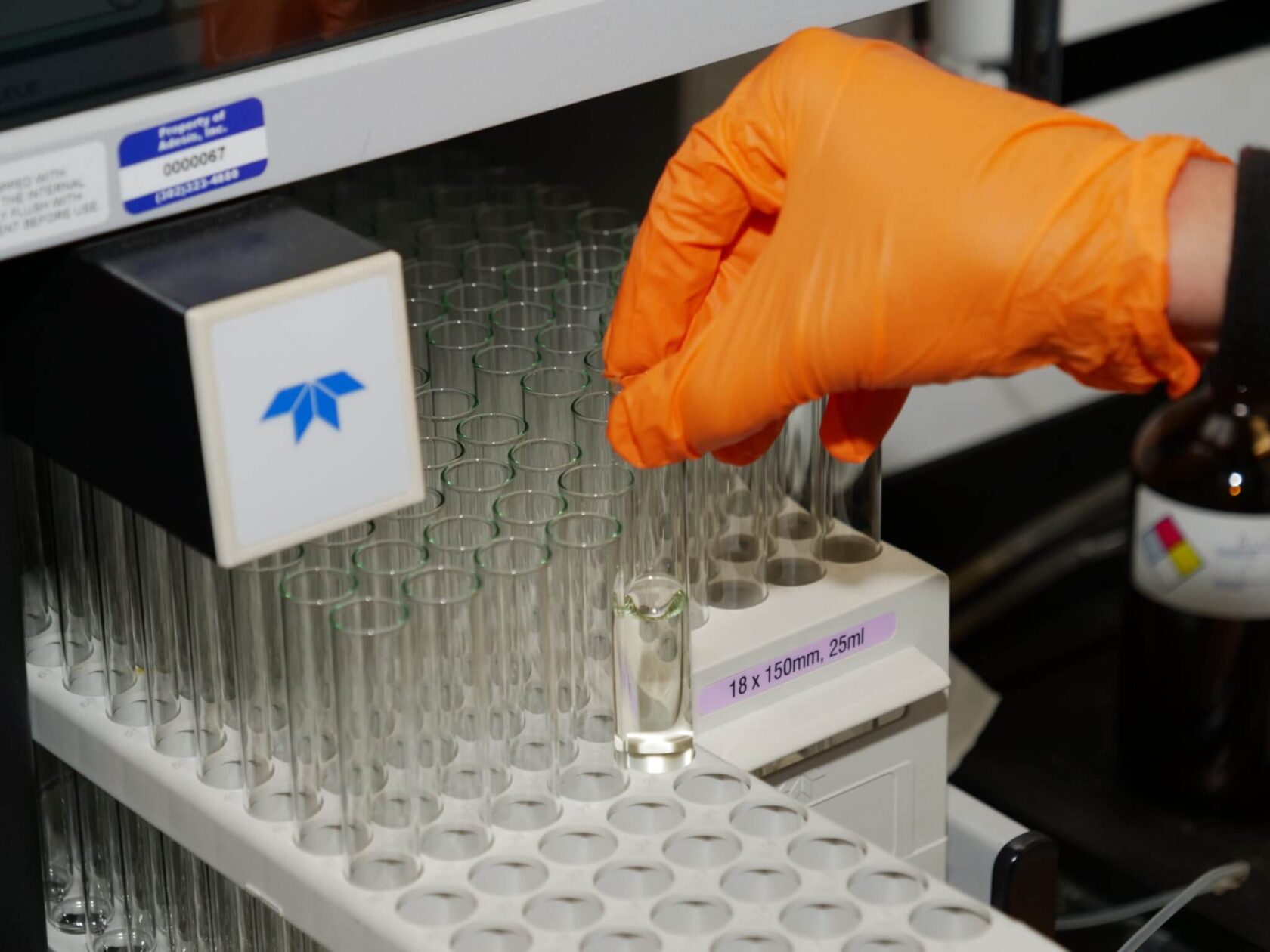

Our analytical chemistry capabilities range from simple analyses through complex chiral method development and experimentation.

- Multi-nuclei 300 & 400 MHz NMR spectrometers

- HPLC-MS and UPLC-MS systems with photo diode array detectors and single quad mass spectrometers

- Dedicated HPLC systems for chiral and normal phase chromatography

- Gel permeation chromatography with refractive index (RI) detector

- Evaporative light scattering detector (ELSD) and charged aerosol detector (CAD) for HPLC

- On-demand LC-MS & GC-MS systems for R&D

- GC-MS systems with single quad mass spectrometers

- GCs with flame ionization (FID) and thermal conductivity (TCD) detectors

- Prep LC systems

- X-Ray diffractometer (PXRD)

- Differential scanning calorimeter (DSC) and thermogravimetric analyzer (TGA) for thermal analysis