Process Development and Specialty Manufacturing Expertise

When companies come to Adesis for help with their chemistry, one of the main reasons is our ability to take a chemical reaction that works on a small scale – usually less than a kilogram – and develop the process so it works on a manufacturing scale.

Before a synthetic scheme can be scaled, it must be optimized, taking into consideration economic feasibility, timelines, and safety concerns. Process chemists are specially trained to keep those factors in mind as they transition a chemical process from small-scale to the multi-kilogram or multi-ton scale. An entire arsenal of process chemistry techniques is available to aid in the optimization of a synthetic scheme, but one of the most powerful tools is the statistical design of experiments (DoE) process.

The DoE Process

Rather than making individual tests one at a time, the DoE process varies test parameters simultaneously, generating more information in fewer experiments. This gives a full picture of the design space, allowing for the largest number of gains in process optimization efforts.

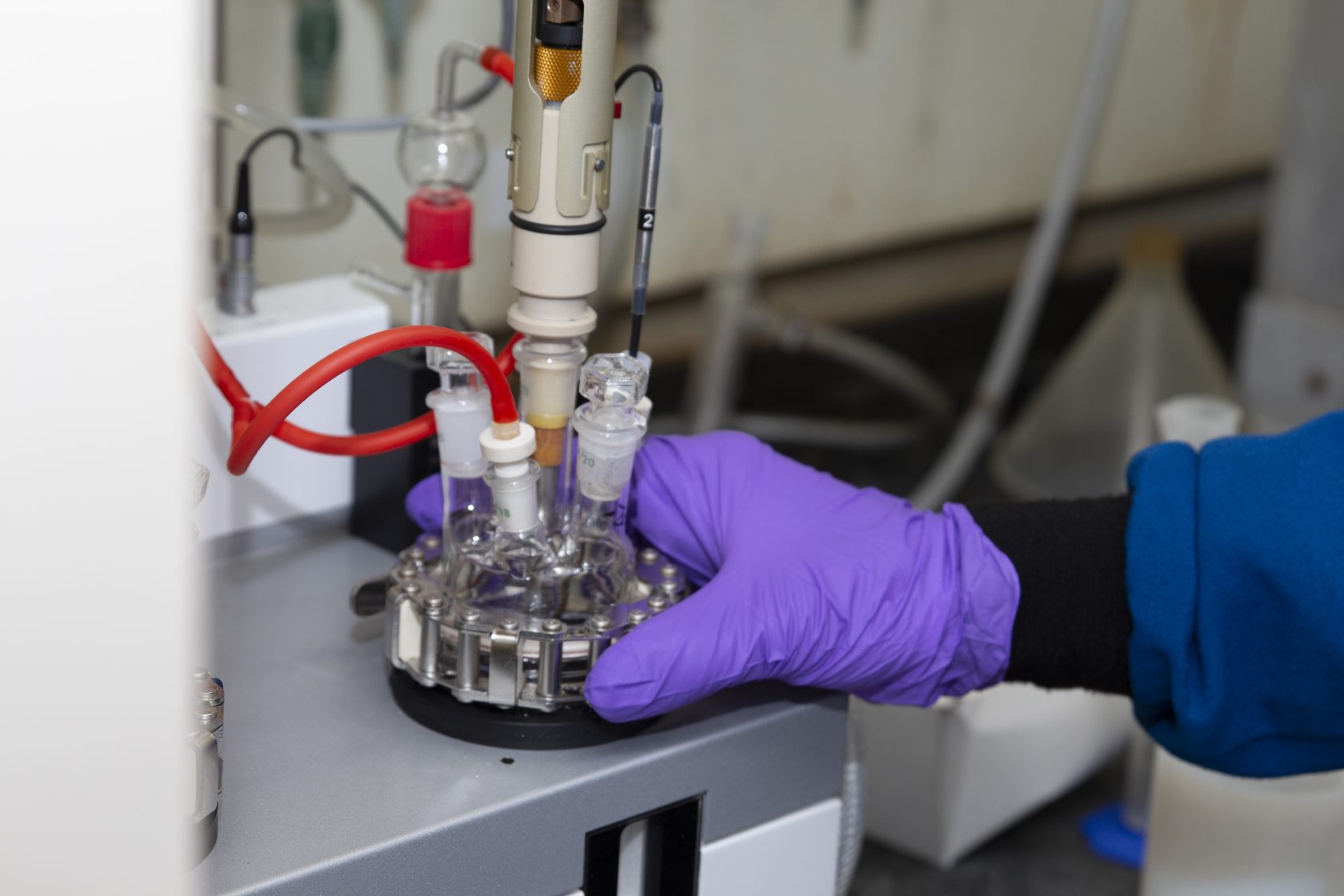

The Adesis process chemistry team is well-versed in DoE methodology and possesses all the DoE software and reactor equipment to conduct quick and precise DoE experiments. Using DoE process optimization, Adesis can optimize and characterize your chemical process to meet your specific manufacturing goals and ensure your confidence in process robustness before moving into full-scale manufacturing.

Once an optimal process is determined, Adesis scientists can focus on how to scale that process up to an industrial level of production through our process development group. Through four stages, this group determines a route of syntheses; tests how to make the process shorter and more efficient; identifies ways to yield quicker deliveries of larger quantities to support pre-clinical studies; and enables the manufacturing of the end-product molecule on a multi-kilogram scale.

Human Expertise and Specialized Equipment

Adesis maintains both the human expertise and the specialized equipment needed to work through all these steps. Safety is paramount when transitioning from small-scale benchtop chemistry to a larger scale because factors such as stirring rate, concentration, exotherms and others might be easily managed on small-scale but require process chemistry experience to manage safely as the scale increases.

Beyond the scope of reaction optimization for scalability, the Adesis process development group possesses unique knowledge in the realm of isolation and purification on larger scale to avoid costly, inefficient workups and chromatography steps leading to further reductions of time, effort, and costs associated with chemical manufacturing.